posted on December 26, 2018 17:56

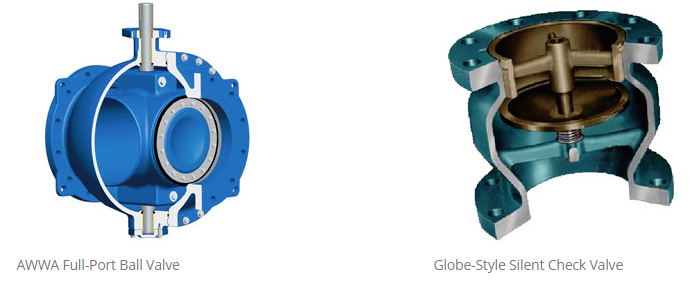

Valve body geometry dictates the general flow area through the valve. Some control valves restrict the flow area to below 80% of the pipe area. Also, the internal contours of the body and seat should be smooth to avoid creating excessive turbulence. The design of the closure member is also important in reducing headloss. The lowest headloss will be achieved if the closure member rotates out of the flow path. A full-port ball valve has the lowest headloss because when the valve is open, the flow path is the same as a straight length of pipe.

There is a direct relationship between headloss in the valve and energy consumption of the pump. As an example, energy costs represent the consumption of kilowatt hours of electricity with a typical cost of about $ 0.08 per kW-hr. The headloss from valves can be converted into an annual energy cost related to the electrical power needed by the pump to overcome the additional headloss from the valve with the equation:

A = (1.65 Q ΔH C U) / E

Where:

A = annual energy cost, $ per year

Q = flow rate, gpm

ΔH = head loss, feet of water

C = cost of electricity, $/kW·hr

U = usage, percent x 100 (1.0 equals 24 hours per day)

E = efficiency of pump and motor set (0.80 typical)

For example, the difference in headloss between a 12 in AWWA ball valve (K = 0.03) and a silent check valve (K = 3.00) in a 3500 gpm or 9.93 ft/sec water system can be calculated as follows:

ΔH = (3.00 – 0.03) (9.93)2 / 2·32.2 = 4.55 feet of water column

This difference in headloss can then be used to calculate the difference in annual operating costs assuming an electricity cost of $ 0.08 per kW-hr. and 50% usage.

A = (1.65 x 3500 x 4.55 x 0.08 x 0.5) / (0.8) = $ 1314

The calculation shows that the use of a 12 in ball valve in the place of a 12 in silent check valve can save $1314 per year in energy costs. If the pump station had four such valves operating for 20 years, the total savings would be $105,100 every 20 years. It is clear that the pumping costs can be more significant than the installed costs of the valves. Further, the larger the valve, the greater the impact from the energy costs.

Use the Val-Matic Energy Calculator to automatically compare the energy cost of various valve types in water service.

Author: Val-Matic